Are Swiss Army Knives still made in Switzerland? The answer to that question is a resounding yes, and the commitment of Victorinox to keeping the knives Swiss-made is at the core of the company's culture. Since 1884, Victorinox's founding family, the Elseners, have worked to keep the manufacturing of every Swiss Army knife (and all of the jobs created by the process) in Switzerland.

The factory in Ibach, Switzerland makes all of the Victorinox Swiss Army Knives and Victorinox Kitchen Knives sold around the world.

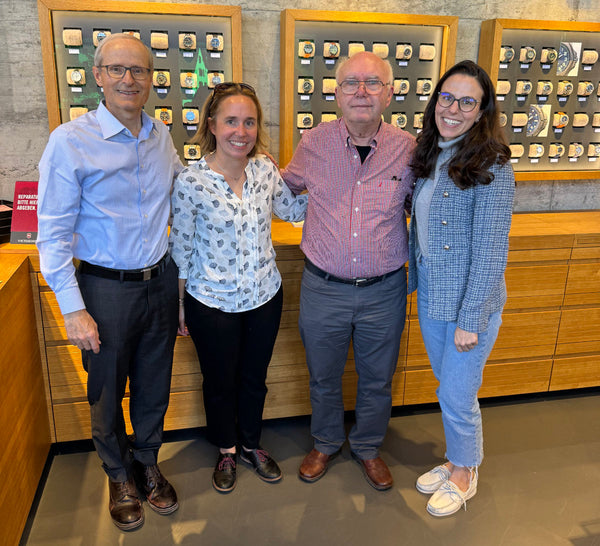

After over 20 years of selling Swiss Army Knives, we recently had the opportunity to visit the Victorinox Swiss Army factory in Ibach to meet Carl Elsener IV, the current president of Victorinox, and his daughter Marie Louise Elsener, who also works in the family business.

The factory is nestled in a quaint, beautiful town in the Swiss Alps with mountain views in every direction and out of every window.

We began our visit with a factory tour and some shopping at the factory store, and ended with a lovely lunch with Carl and Marie Louise at a traditional Swiss restaurant.

Pictured above: Carl Elsener, Heather Elmer, Keith Thompson and Marie Louise Elsener

As Victorinox uses a combination of pre-made and proprietary production machines the Victorinox engineers have created and built just for their factory, photographs of machines and automated processes are not allowed during the tour. We did ask permission to snap a few photos here and there that wouldn't give away any of the company secrets, and will share those here.

Note: If you are headed to Switzerland, please note that Victorinox does not offer factory tours to the public.

Exploring the Production Process

During the tour, we were able to see every step of the manufacturing process. The first stop was a section of the warehouse where the rolls of steel are stored prior to being shaped into Swiss Army knife and kitchen knife components.

Victorinox keeps a stockpile of steel sufficient for many months of production to protect the manufacturing process from any disruptions. In this photo, we are surrounded by a portion of the steel ready for use just within the next couple of days.

Putting it All Together - Swiss Army Knife Assembly

Many of the standard Swiss Army Knife models such as the Classic SD are assembled by machines. Even the tiny little key rings can be added by machine. (A very interesting and precise process.)

All of the steel tool components, spacers, liners and rivets are fed into an assembly machine, and they are put together in a very specific order. The knife then moves on to have the famous red (or any color!) handle scales attached. Finally, it's time for accessories like toothpicks, pens and tweezers to be added.

Every Swiss Army Knife is tested before being boxed and shipped out to its final destination.

There are some knife models that are still hand assembled. Our exceptional tour guide told us that the manual knife assembly department is comprised entirely of women, as they have not had luck finding men with the knack for this particular job.

As we walked through, the women were snapping the knives together with jaw-dropping speed and precision. The number of knives each one of them makes in a day is impressive!

The speed of this team became even more astounding to us when we reached the portion of the tour when it was our turn to hand-assemble a knife of our own.

I'm sure we would have been fired within the first day due to low production numbers!

A Dedication to Sustainability

In addition to the ingenious machinery and processes that go into building Swiss Army Knives, Victorinox also puts significant research and resources toward sustainability. Everything possible is recycled and repurposed, including the microscopic steel shavings from blade sharpening and polishing which are formed into pucks and then re-formed into usable stainless steel.

A Sweet End to the Day

At lunch, Carl told us the Flechlin, the Swiss chocolatier that makes the sweet chocolate version of the Swiss Army Knife, is just down the road from the Victorinox factory. We ended the day with a visit, of course. What is more Swiss than Swiss Army Knives and wonderful chocolate?